Project Background

MicroTech Semicon GmbH (fictional but modeled on real semiconductor manufacturers), located in Munich, Germany, is a leading producer of 200mm and 300mm semiconductor wafers. As market demand in Europe accelerates, the company faced several challenges during its capacity expansion:

- Rapid growth in wafer inventory

- Extremely high requirements for cleanliness and operational stability

- Heavy dependence on manual handling with elevated error rates

- Limited warehouse height but a need for higher storage density

- Full integration with the existing MES (Manufacturing Execution System)

To resolve these issues, the company initiated an upgrade to an AS/RS-based intelligent warehouse, selecting Dongjian’s customized automated storage solution for the semiconductor sector.

Project Scale

| Parameter | Data |

|---|---|

| Total Warehouse Area | 420 m² (inside cleanroom) |

| Clear Height | 9.2 m |

| Storage Carrier Type | FOUP / SMIF wafer boxes |

| Effective Storage Positions | 4,800 |

| Pallet Locations | 1,200 |

| Automation Equipment | 2 twin-mast stacker cranes, tote conveyor system, automated scheduling system |

| Software Integration | WMS + WCS + MES interface |

| Project Duration | 4.5 months (including installation and cleanroom commissioning) |

Solution Overview

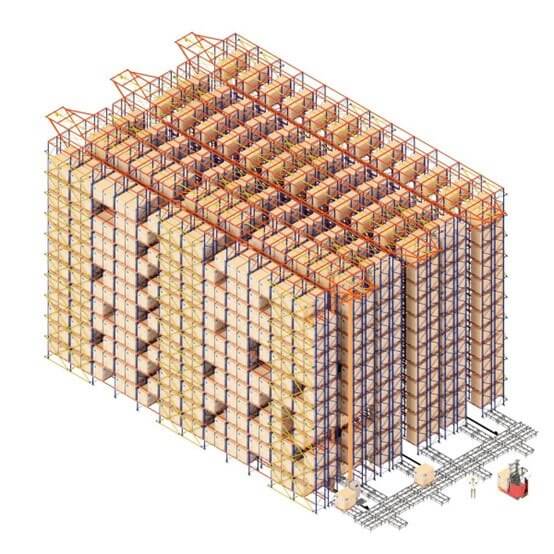

Dongjian delivered a full-process, semiconductor-grade intelligent warehousing system, consisting of high-precision storage structures, automated handling equipment, and tight digital integration.1. Precision Racking System

Designed specifically for cleanroom operation and sensitive wafer materials, the racking system includes:

- Fully enclosed anti-static coating

- Customized FOUP / wafer box pallet interfaces

- High-strength, lightweight upright structures

- 9.2-meter high-bay racks with ±2 mm tolerance

The structural precision meets the strict safety and cleanliness standards of the European semiconductor industry.

2. Intelligent Stacker + Conveyor System

Two high-speed twin-mast stacker cranes deliver:

- Single cycle time ≤ 18 seconds

- Continuous 24/7 operation

- Intelligent route planning with dynamic obstacle avoidance

- Automatic task exchange with MES/WMS

The conveyor line ensures contactless transfer of FOUPs and raw materials between warehouse and production lines.

3. Asymmetric Aisle Design

Considering the space constraints of the German facility and the lack of space for conveyors at the aisle ends, Dongjian engineered a customized layout featuring:

- Two asymmetric aisles with different widths

- 8.5-meter cantilever racking system

- Special bottom support structures designed for load capacity and cleanroom standards

This configuration minimizes mechanical interference and ensures smooth stacker crane operation.

4. On-Site Installation & Commissioning

Germany enforces highly stringent safety and installation regulations. Dongjian’s team completed:

- Full CE-compliant installation procedures

- Cleanroom wiping and secondary packaging

- Verticality and load-bearing tests

- Data integration testing between the control room and MES

The system passed customer acceptance on the first attempt.

Project Results

| Indicator | Before | After |

|---|---|---|

| Warehouse Space Utilization | 52% | 89% |

| Single Storage Cycle Time | 65 sec | 18 sec |

| Operators Required | 9 | 3 |

| Material Error Rate | 0.32% | 0.01% |

| Wafer Box Contamination Rate | — | ↓ 60% |

| Production Line Interface Efficiency | — | ↑ 2.8× |

Through this upgrade, the semiconductor manufacturer achieved:

- High-density, high-cleanliness storage

- Automated and stable material delivery

- Improved wafer yield

- Significantly enhanced operational efficiency