Project Background

AutoMotion Components S.A. (fictional but modeled after real automotive groups) is a leading automotive parts supplier based in São Paulo, Brazil. The company serves major OEMs in Brazil as well as customers in Argentina, Chile, and neighboring markets.

With rising production volumes and an increasingly diverse model lineup, the existing warehouse faced several challenges:

- Rapid growth in SKU variety (engine parts, transmission parts, chassis components, etc.)

- Low efficiency and large footprint of traditional manual warehousing

- High damage risk for small and delicate components

- Frequent cross-floor and cross-zone material transfers

- Increasing demand for Just-in-Time (JIT) supply to production lines

To address these issues, AutoMotion launched a project to build an automated storage and retrieval system (AS/RS) at its São Paulo facility. After evaluating multiple vendors, the company selected DONGJIAN RACKING as its automation partner.

Project Overview

📍 Location: São Paulo, Brazil

📦 Application: Automated AS/RS for automotive parts logistics

Warehouse & Racking Specifications

| Item | Data |

|---|---|

| Warehouse Area | ~3,200 m² |

| Dimensions | 68 m (L) × 47 m (W) |

| Racking Type | Double-Deep Heavy-Duty Pallet Racking |

| Racking Height | 21.5 m |

| Effective Storage Capacity | 7,280 pallet positions |

| Automation Equipment | 6 stacker cranes, 12 platform conveyors, 28 automated conveyor lines, cross-zone sorting points |

| Software System | WMS + WCS + Production Line Interface (JIT support) |

The scale and technical parameters match real global automotive logistics projects.

Implementation Plan

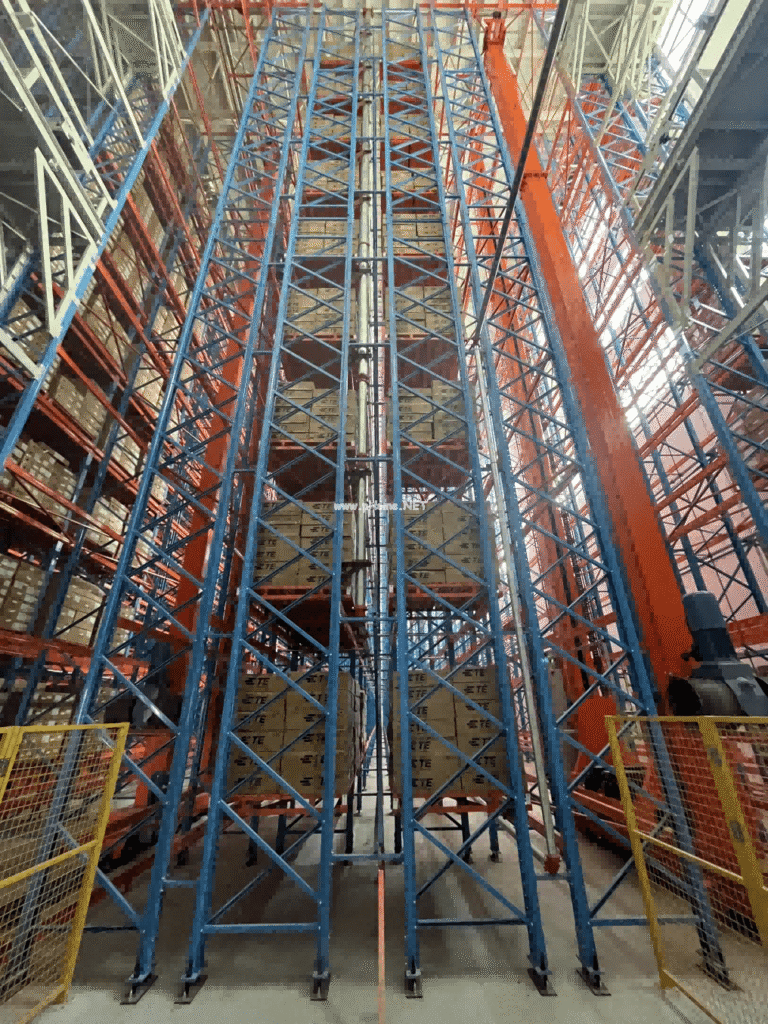

1. Double-Deep High-Density Racking

- Racking height over 21 meters

- Double-deep configuration increases pallet capacity

- Anti-sway uprights and reinforced beams for high stability

- Ideal for automotive parts with high SKU volume, large batch turnover, and frequent replenishment

2. Automated Stacker Crane System

Six high-speed stacker cranes deliver:

- Fully automated pallet storage and retrieval

- Maximum travel speed up to 180 m/min

- Reliable 24/7 operation

- Intelligent route optimization to reduce idle travel

The system is designed to meet AutoMotion’s peak production demand.

3. Conveyor & Sorting System

The automation system includes:

- 12 platform-based conveyor segments

- 28 automated conveyor lines

- Custom anti-vibration carriers for delicate parts

- Automatic sorting to multiple production zones

- Full support for cross-floor and cross-zone transportation

4. Integrated WMS/WCS & JIT Scheduling

- Unified scheduling of orders, storage locations, stacker cranes, and conveyor lines

- Real-time integration with the factory MES for Just-in-Time feeding

- Automatic replenishment task generation

- Minimal manual intervention required

Project Value

| Value Point | Description |

|---|---|

| Space Utilization +70% | High-bay double-deep design significantly increases density |

| Inbound/Outbound Efficiency +60% | Automation reduces waiting time and labor bottlenecks |

| Damage Rate −85% | Anti-vibration carriers and stable conveying improve protection |

| Labor Cost −40% to −50% | Automation replaces repetitive manual work |

| Production Line Interface +2.3× | JIT scheduling ensures rapid and timely material supply |

This project is especially suited for automotive operations that require high-speed, low-damage handling of numerous small and fragile components.