The drive-in pallet racking system is a high-density warehouse storage solution designed to maximize available space by significantly reducing the number of aisles. Forklifts drive directly into the racking structure to store pallets in deep lanes, making it ideal for bulk storage operations.

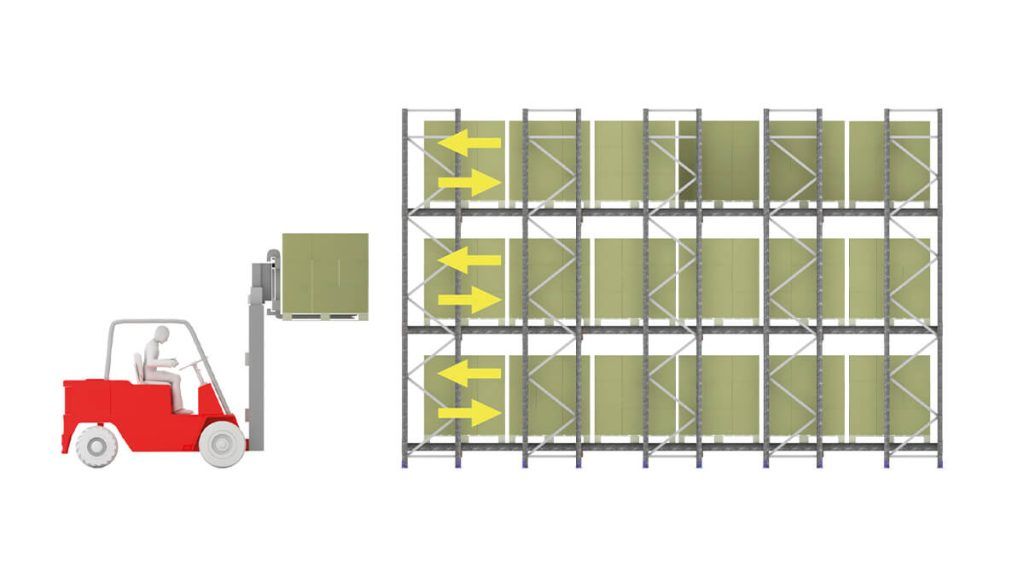

This system follows the Last-In, First-Out (LIFO) inventory principle and is widely used in warehouses where high storage density is more important than individual pallet accessibility.

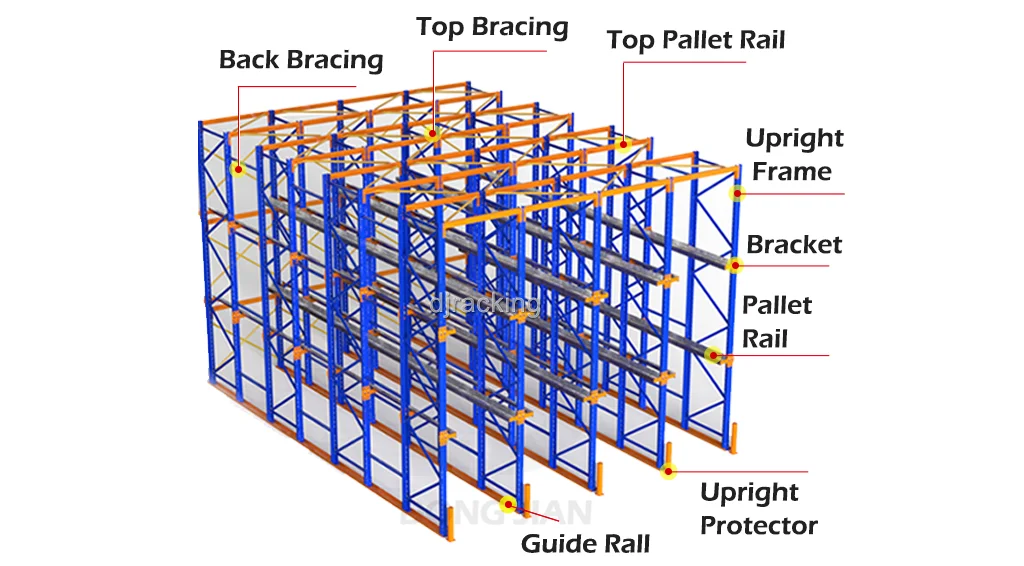

Drive-in pallet racking allows forklifts to enter the rack lanes and place pallets onto horizontal support rails fixed to the uprights. Pallets are stored one behind another within the same lane, creating a compact and space-efficient storage block.

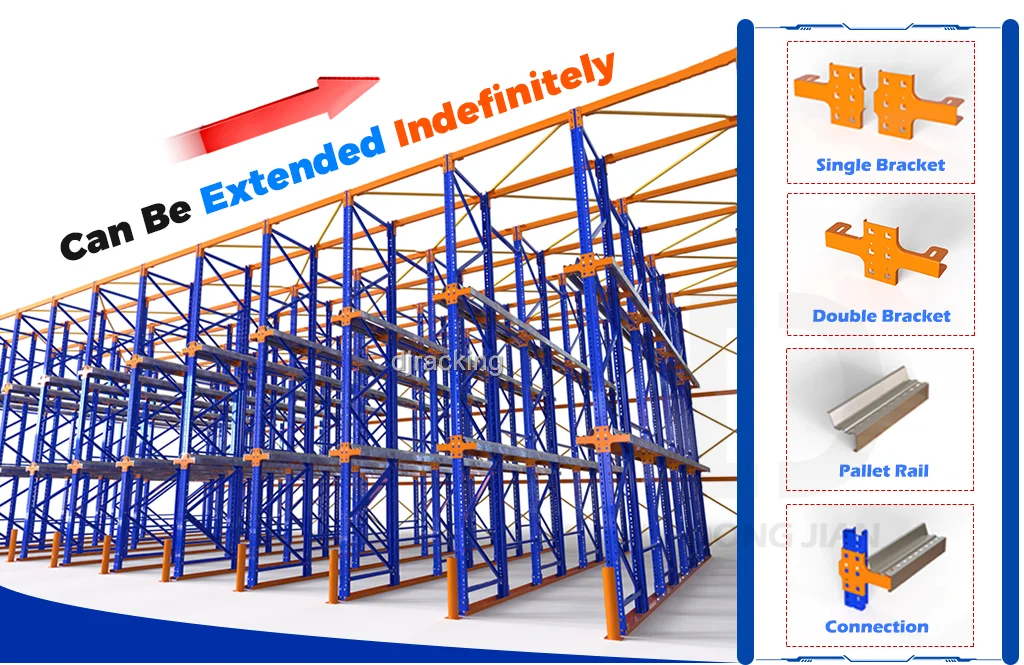

By eliminating multiple working aisles, drive-in racking achieves one of the highest storage densities among pallet racking systems.

Drive-in racking dramatically increases pallet positions per square meter by reducing aisle space. It is an effective solution for warehouses with limited floor area or high land costs.

With fewer aisles and more pallet locations, the system lowers the overall cost per pallet stored compared to conventional selective racking.

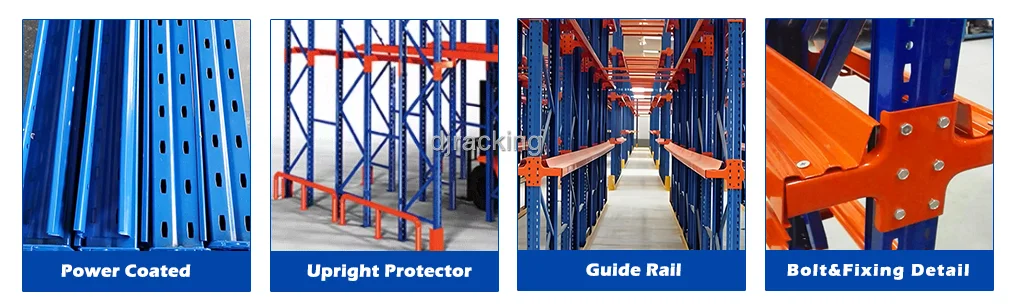

Manufactured from high-strength steel and finished with powder coating, the racking system provides excellent load capacity, corrosion resistance, and long-term durability.

Rack height, lane depth, load capacity, and layout can be customized to suit pallet size, forklift type, and warehouse configuration.

Forklifts enter storage lanes from a single access aisle

Pallets are placed on support rails inside the rack

Multiple pallets are stored in depth per lane

Inventory flow operates on a LIFO basis

This design minimizes travel distances and maximizes cubic space usage.

High-density multi-deep pallet storage

Powder-coated heavy-duty steel structure

Reinforced uprights and load rails

Forklift guide rails for safe entry

Optional upright protectors and backstops

Compatible with counterbalance and reach trucks

Drive-in pallet racking is best suited for:

Warehouses storing large quantities of the same SKU

Cold storage and refrigerated warehouses

Food and beverage distribution centers

Manufacturing raw material storage

Buffer and bulk storage areas

Extremely high storage density

Reduced warehouse footprint

Lower investment per pallet position

Suitable for heavy loads and tall installations

Limited pallet selectivity

Not suitable for operations with many different SKUs

Inventory rotation follows LIFO principle

| Feature | Drive-In Racking | Drive-Through Racking |

|---|---|---|

| Forklift Access | Single-side | Two-side |

| Inventory Flow | LIFO | FIFO |

| Storage Density | Very High | High |

| Pallet Selectivity | Low | Medium |

| Typical Use | Bulk storage | FIFO-required storage |

To enhance safety and prolong system life, drive-in racking can be equipped with:

Upright protectors

Guide rails

Pallet backstops

Ground rails

Reinforced entry frames

These components help reduce forklift impact damage and ensure safe daily operation.

Designed for high-density warehouse optimization

Proven structural strength and stability

Custom-engineered layouts for each project

Suitable for standard and cold storage environments

Professional technical support from design to installation

Looking to increase warehouse storage capacity without expanding your facility?

Contact us today to receive a customized drive-in pallet racking solution based on your warehouse layout, pallet dimensions, and operational requirements.

👉 Request a Quote

👉 Download Technical Specifications

👉 Speak with a Storage Specialist

Heavy-duty racking, engineered for high load.

Custom design to fit your warehouse.

High-strength steel, built to last.

From design to installation, one-stop solution.

Request a quick quote for racking solutions.

We reply within 24 hours.

Fast quote for pallet, shuttle, AS/RS & customized racks.