When planning a high-density warehouse storage solution, drive-in racking and drive-through racking are often compared.

They look similar, serve similar purposes, and are both designed to maximize storage space.

However, the difference between drive-in and drive-through racking directly affects inventory flow, operational efficiency, and long-term warehouse performance.

This guide explains the differences clearly and helps you decide which system fits your warehouse operation—without focusing on product specifications or sales.

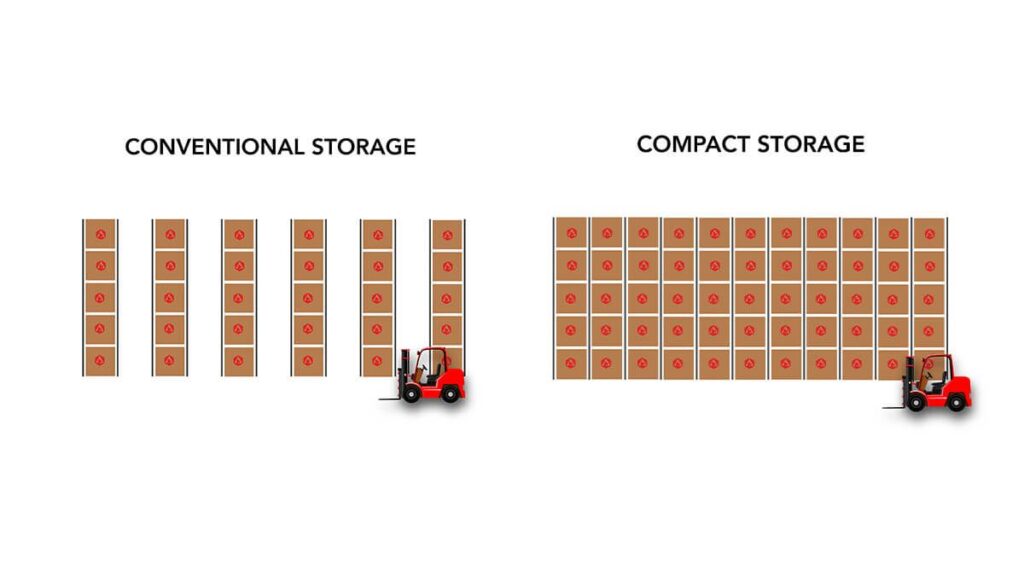

What Problem Do Drive-In and Drive-Through Racking Solve?

Both systems are designed to increase pallet storage density by reducing the number of aisles in a warehouse.

Instead of accessing pallets from multiple aisles, forklifts enter the racking lanes directly.

This approach is especially useful when:

- Warehouse space is limited

- Large quantities of the same SKU are stored

- Vertical space needs to be fully utilized

The key difference lies in how pallets move in and out of storage.

How Drive-In and Drive-Through Racking Work

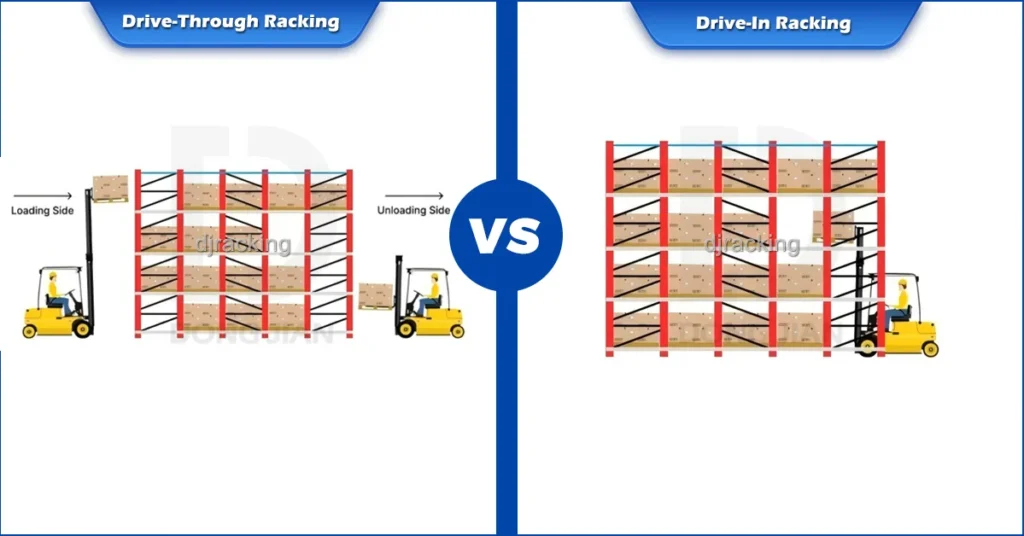

Drive-In Racking (LIFO System)

Drive-in racking operates on a Last-In, First-Out (LIFO) principle.

- Forklifts enter the racking from one side

- Pallets are stored and retrieved from the same access point

- The last pallet placed is the first one removed

This system prioritizes maximum space utilization over inventory rotation.

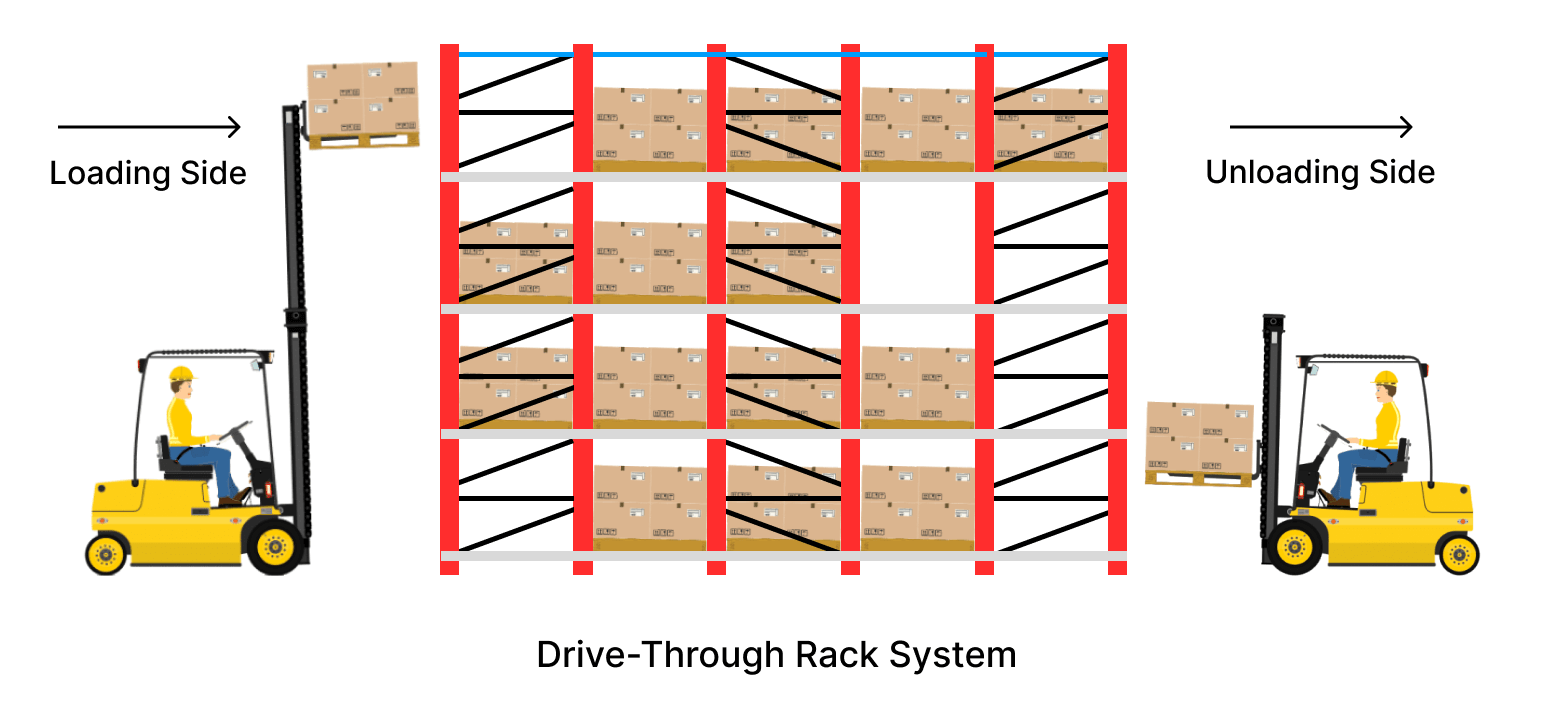

Drive-Through Racking (FIFO System)

Drive-through racking operates on a First-In, First-Out (FIFO) principle.

- Forklifts load pallets from one side

- Pallets are retrieved from the opposite side

- The first pallet stored is the first one picked

This design supports better inventory rotation and process flow.

Key Differences Between Drive-In and Drive-Through Racking

| Aspect | Drive-In Racking | Drive-Through Racking |

|---|---|---|

| Inventory Flow | LIFO | FIFO |

| Forklift Access | One side | Two sides |

| Storage Density | Very high | High |

| Inventory Rotation | Limited | Efficient |

| Typical Focus | Space maximization | Stock control & flow |

This comparison highlights why the two systems are used in different operational scenarios, even though their structures appear similar.

Which Racking System Should You Choose?

Choose Drive-In Racking If:

- You store large volumes of the same SKU

- Inventory turnover is not critical

- Space utilization is your top priority

- Your warehouse focuses on bulk storage

Typical applications include:

- Cold storage

- Frozen food warehouses

- Raw material storage

Choose Drive-Through Racking If:

- FIFO inventory management is required

- Products have expiration dates

- Stock traceability matters

- Operational flow needs to be optimized

Typical applications include:

- Food and beverage distribution

- FMCG warehouses

- Pharmaceutical storage

Cost and Operational Considerations

From an operational perspective:

- Drive-in racking generally requires a lower initial investment

- Drive-through racking often costs more due to additional access points and structural requirements

However, cost should not be evaluated on installation alone.

Operational efficiency, picking accuracy, and inventory control often outweigh initial savings over time.

Common Mistakes When Choosing Between Drive-In and Drive-Through Racking

Many warehouse projects run into problems because of early-stage selection errors:

- Choosing drive-in racking without considering future SKU expansion

- Ignoring forklift maneuverability and operator safety

- Overlooking inventory rotation requirements

- Focusing only on storage density instead of total warehouse efficiency

Avoiding these mistakes early can prevent expensive layout changes later.

Quick Decision Summary (10-Second Guide)

- Same SKU, maximum density → Drive-In Racking

- FIFO inventory required → Drive-Through Racking

- Cold storage with bulk goods → Drive-In Racking

- Expiration-sensitive products → Drive-Through Racking

This summary format is intentionally designed for AI search snippets and quick answers.

Final Thoughts

There is no universally “better” system between drive-in and drive-through racking.

The right choice depends on inventory flow, storage strategy, and long-term warehouse operations.

If your warehouse handles complex inventory or is expected to scale, evaluating these factors early helps ensure the racking system supports—not limits—your operation.

To explore how each system is typically designed and applied in real projects, you can learn more through detailed overviews of drive-in and drive-through racking solutions.