Choosing the right warehouse storage system is not always about selecting the strongest or most common option. In many facilities, longspan racking delivers better efficiency, flexibility, and cost control than pallet racking—when used in the right context.

This guide explains what longspan racking is, how it works, and when it should (and should not) be used, so you can make an informed warehouse storage decision.

What Is Longspan Racking?

Longspan racking is a medium-duty warehouse shelving system designed for storing goods that are handled manually rather than by forklift.

It is commonly used for:

- Cartons and boxed inventory

- Loose or mixed SKUs

- Spare parts and components

- Items with frequent picking and restocking

Unlike pallet racking systems, longspan racking prioritizes direct human access, making it especially effective in warehouses with diverse inventory sizes.

How Longspan Racking Works in Practice

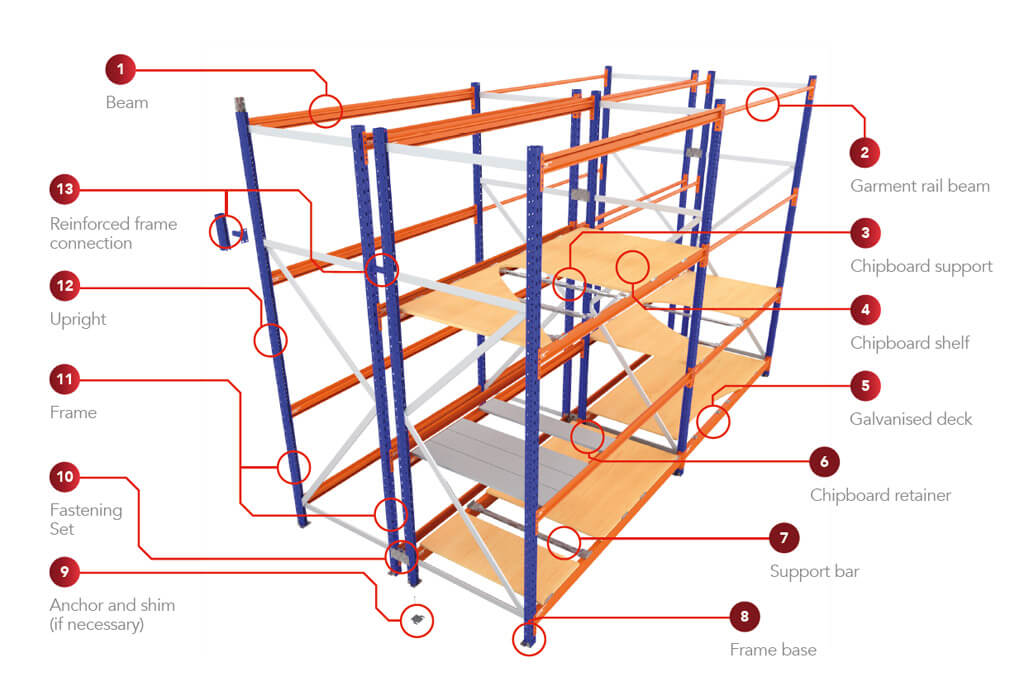

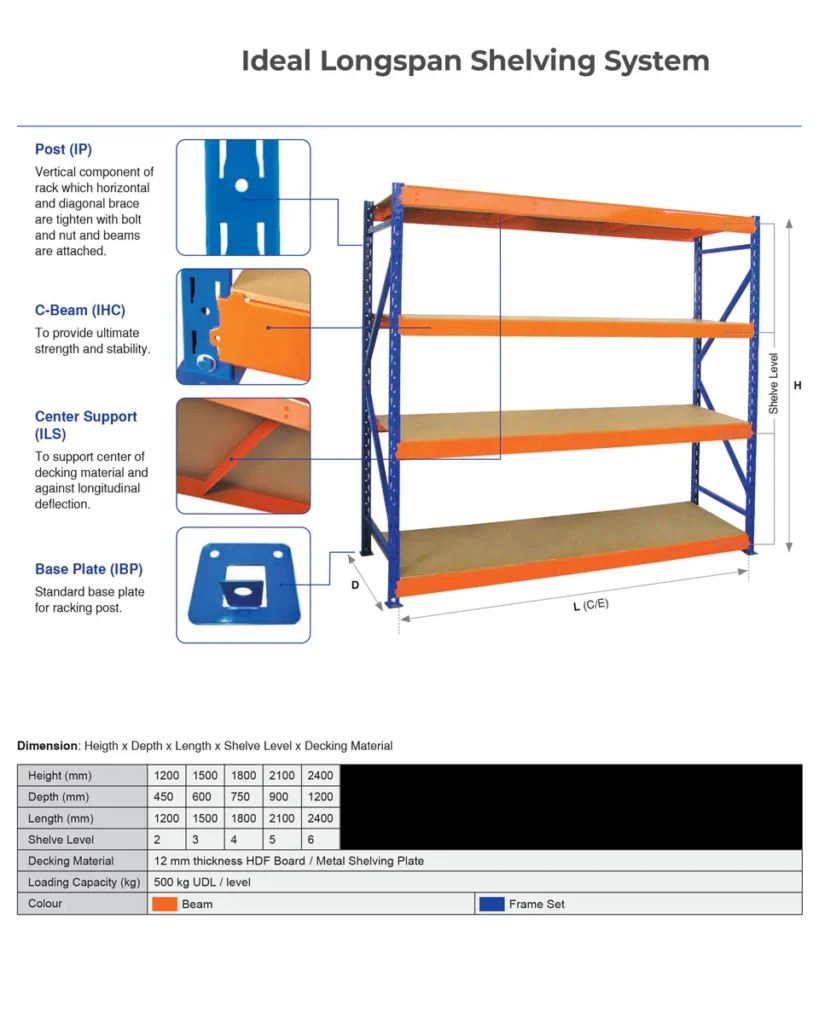

Longspan racking systems are built around adjustable horizontal beams and decking panels. Shelf heights can be modified easily, allowing warehouses to adapt layouts as inventory changes.

In daily operations, this means:

- Faster manual picking

- Less wasted vertical space

- Easier reconfiguration without heavy equipment

This operational flexibility is one of the main reasons longspan racking is widely used in dynamic storage environments.

When Longspan Racking Is the Best Choice

Longspan racking is particularly effective when:

- Goods are not stored on pallets

- Inventory sizes vary significantly

- Manual picking is the primary workflow

- Storage layouts change frequently

- Forklift use is limited or unnecessary

Typical applications include:

- E-commerce fulfillment centers

- Maintenance and spare-parts warehouses

- Light manufacturing storage areas

- Distribution centers with mixed SKU profiles

In these environments, pallet racking often becomes oversized and inefficient.

Longspan Racking vs Pallet Racking: A Decision Perspective

Rather than asking which system is “better,” the correct question is which system matches your operation

| Decision Factor | Longspan Racking | Pallet Racking |

|---|---|---|

| Picking method | Manual | Forklift |

| Inventory type | Cartons, loose goods | Palletized loads |

| Layout flexibility | High | Moderate |

| Investment level | Medium | High |

| Change frequency | Easy | Limited |

If forklifts are required for daily access, pallet racking is the logical choice.

If people handle products directly, longspan racking often delivers better efficiency.

Common Longspan Racking Layouts

Longspan systems are highly adaptable and can be configured as:

- Single-row shelving along walls

- Double-sided rows for central warehouse aisles

- Multi-level storage areas for maximizing vertical space

- Hybrid zones combined with other shelving or racking systems

The layout choice depends more on workflow design than on load capacity alone.

Why Longspan Racking Is Often Misunderstood

Many warehouses default to pallet racking because it is widely recognized as an “industrial standard.” However, this leads to common issues:

- Over-engineering for lightweight goods

- Reduced picking efficiency

- Higher costs without operational benefit

Longspan racking is not a compromise—it is a purpose-built solution for specific storage needs that pallet racking is not designed to serve.

Key Considerations Before Choosing Longspan Racking

Before implementing a longspan racking system, warehouses should evaluate:

- Maximum item weight per shelf

- Frequency of picking activity

- Future inventory changes

- Available floor and ceiling space

- Safety and load distribution requirements

Proper planning ensures long-term usability without frequent reconfiguration.

Frequently Asked Questions

Is longspan racking suitable for industrial warehouses?

Yes. Longspan racking is widely used in industrial environments where manual handling is required.

Can longspan racking be reconfigured later?

Yes. One of its key advantages is adjustability and modular expansion.

Does longspan racking replace pallet racking?

No. It complements pallet racking and serves different operational purposes.

Final Thought: Choose the System That Fits the Workflo

Longspan racking works best when storage design follows real operational behavior, not assumptions.

Warehouses that prioritize flexibility, manual access, and mixed inventory often achieve better efficiency by choosing longspan racking over heavier systems designed for pallets.

Looking for a configurable longspan racking system for your warehouse?

👉 Explore our longspan racking solutions