Cantilever racking is a highly efficient storage solution designed for long, bulky, or irregularly shaped items such as timber, steel profiles, pipes, and panels. With its open-front design and modular structure, cantilever racking provides direct access, excellent load visibility, and maximum storage flexibility for industrial and warehouse environments.

Our cantilever racking systems are engineered to support a wide range of load requirements and can be configured for both indoor and outdoor applications.

Cantilever racking is a type of warehouse storage system consisting of vertical uprights and horizontal arms that extend outward to support loads. Unlike traditional pallet racking, it has no front columns, allowing long materials to be stored and retrieved safely and efficiently.

This design makes cantilever racking ideal for storing products that are difficult to handle with standard shelving systems, including long, heavy, or oversized items.

Cantilever racking is widely used across industrial sectors due to its versatility and performance advantages:

Open-front access for easy loading and unloading

Flexible arm positioning to accommodate varying load sizes

Scalable modular design allowing future expansion

High load-bearing capacity for heavy-duty applications

Suitable for indoor and outdoor use, with optional protective finishes

Compared with conventional racking systems, cantilever racking offers superior efficiency when handling long materials and improves overall warehouse productivity.

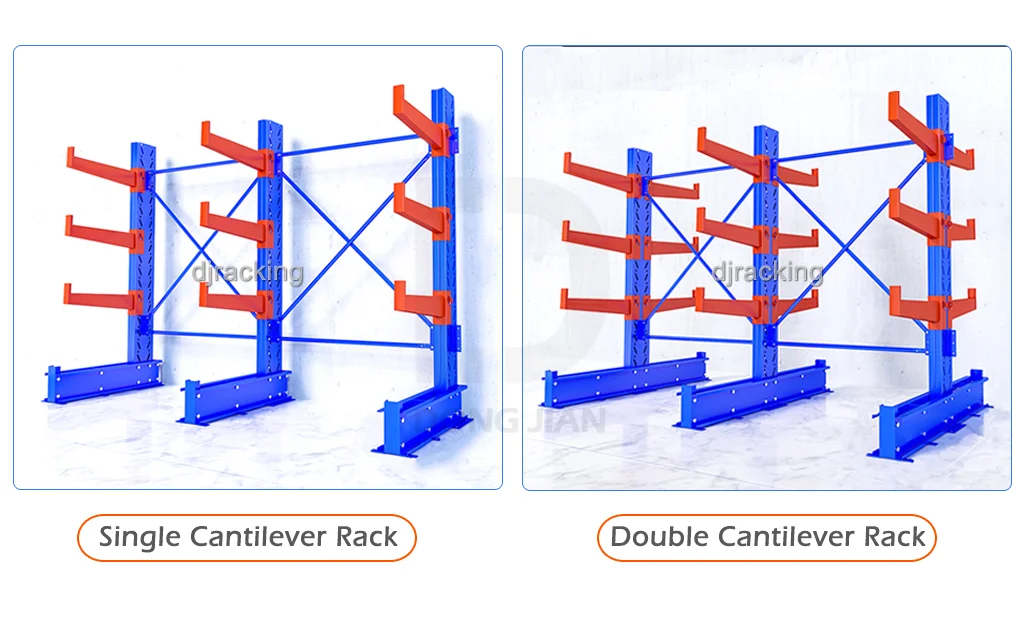

Designed for installation against walls or along warehouse aisles, single-sided cantilever racking maximizes floor space while providing strong support for long loads.

Double-sided systems allow storage on both sides of the upright, offering higher storage density and improved accessibility in open warehouse layouts.

Cantilever racking systems are available in multiple load categories to suit different storage requirements:

Light duty for smaller or lighter materials

Medium duty for general industrial use

Heavy duty for steel, structural sections, and high-load applications

Mobile cantilever racking systems reduce aisle space and increase storage capacity, while outdoor systems are designed with corrosion-resistant finishes for long-term external use.

Cantilever racking systems can be customized to meet specific operational requirements. Typical specifications include:

Arm lengths: configurable to suit load dimensions

Upright heights: adaptable to ceiling height and storage volume

Load capacity per arm: varies by duty level and design

Bay load capacity: engineered according to structural calculations

Surface finishes: painted, galvanized, or corrosion-protected options

All systems are designed to comply with applicable safety and engineering standards.

Cantilever racking is widely used across multiple industries, including:

Timber and lumber storage

Steel bars, beams, and metal profiles

Pipes and tubes

Manufacturing and distribution centers

Building materials and construction supply warehouses

Its adaptability makes it suitable for both raw materials storage and finished goods handling.

Selecting the appropriate cantilever racking system depends on several key factors:

Type and length of stored materials

Load weight and distribution

Required storage capacity and future expansion plans

Indoor or outdoor installation conditions

Handling equipment used (forklifts, cranes, etc.)

A properly designed system ensures optimal safety, efficiency, and long-term performance.

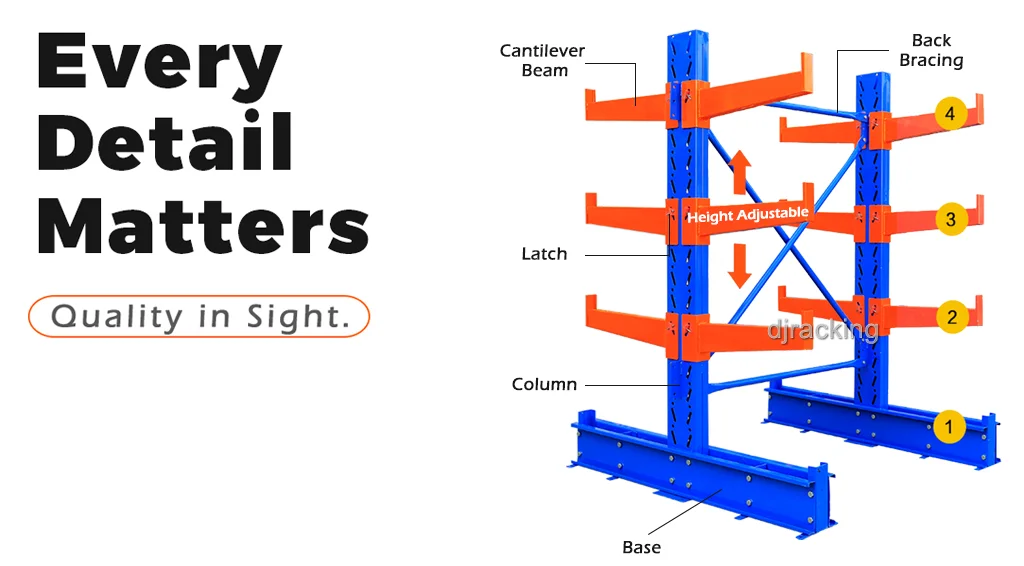

A complete cantilever racking system typically includes:

Vertical uprights

Horizontal load-bearing arms

Base plates and bracing

Arm end stops and safety pins

Optional roofing and cladding for outdoor installations

Each component is designed to work together as part of a robust structural system.

Cantilever racking systems are used worldwide to optimize storage efficiency for long and heavy products. Typical solutions include high-capacity industrial warehouses, outdoor steel storage yards, and manufacturing facilities requiring flexible material handling.

Custom configurations can be developed to suit specific operational needs.

What is cantilever racking used for?

Cantilever racking is used to store long, bulky, or irregularly shaped items such as timber, pipes, steel sections, and panels.

How much weight can cantilever racking hold?

Load capacity depends on system design, arm length, and material grade. Systems can be engineered for light to heavy-duty applications.

What is the difference between single and double-sided cantilever racking?

Single-sided systems are placed against walls, while double-sided systems allow storage on both sides for increased capacity.

Can cantilever racking be used outdoors?

Yes. Outdoor cantilever racking systems are available with galvanized or corrosion-resistant finishes.

Is cantilever racking adjustable?

Yes. Arms can be repositioned to accommodate different load sizes and changing storage requirements.

Whether you require a standard system or a fully customized solution, our cantilever racking systems are designed to meet demanding industrial storage requirements.

Contact us today to discuss your project or request a tailored quotation.

Heavy-duty racking, engineered for high load.

Custom design to fit your warehouse.

High-strength steel, built to last.

From design to installation, one-stop solution.

Request a quick quote for racking solutions.

We reply within 24 hours.

Fast quote for pallet, shuttle, AS/RS & customized racks.