Push back racking is a high-density pallet storage system designed for warehouses that require maximum space utilization with fast pallet handling.

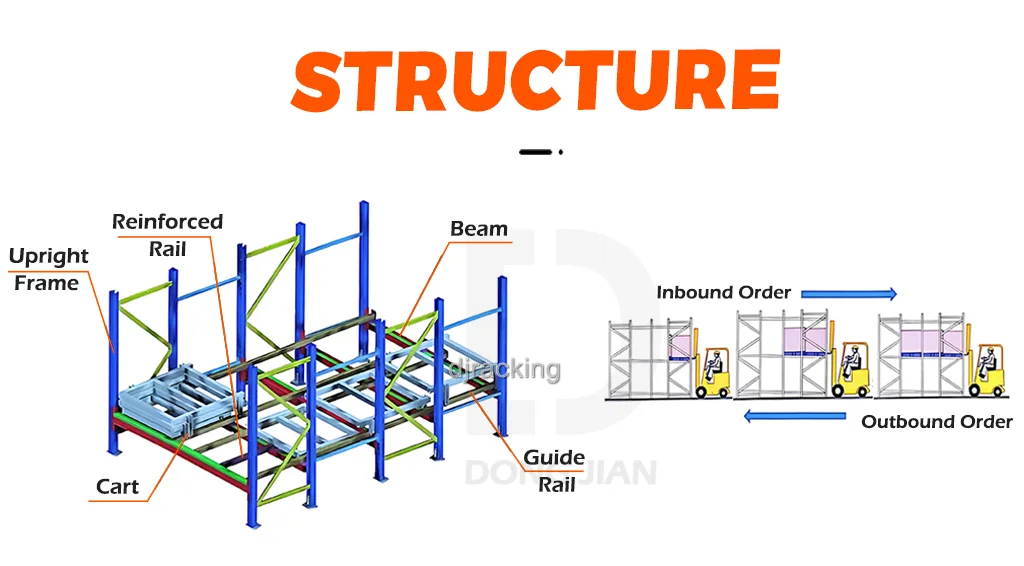

The system operates on a Last-In-First-Out (LIFO) principle, where pallets are stored 2–6 deep per lane on gravity-driven carts that move along inclined rails.

Push back racking is a high-density pallet storage system designed for warehouses that require maximum space utilization with fast pallet handling.

The system operates on a Last-In-First-Out (LIFO) principle, where pallets are stored 2–6 deep per lane on gravity-driven carts that move along inclined rails.

This solution is widely used in operations with low to medium SKU variety, where storage density and throughput are more critical than FIFO inventory rotation.

Storage principle: LIFO (Last-In-First-Out)

Pallet depth: 2 to 6 pallets deep per lane

Handling method: Forklift access from a single aisle

Operating mechanism: Gravity-driven nested carts

Typical environments: Ambient, chilled, and cold storage warehouses

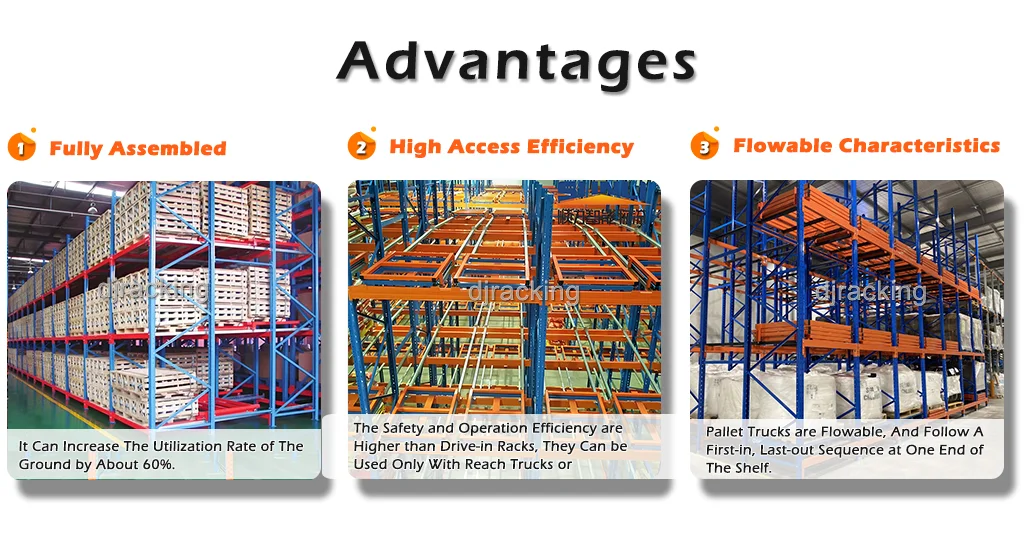

Push back racking systems are selected when warehouse operators need to balance storage density, accessibility, and operational speed.

Main advantages include:

Increased storage density compared to selective racking

Faster pallet handling with reduced forklift travel

Independent SKU per lane (better selectivity than drive-in racking)

Fewer aisles required, maximizing floor space utilization

A pallet is loaded onto the front cart using a forklift

Each new pallet pushes the existing pallets backward along the rail

Carts nest together as pallets are added

During retrieval, gravity returns the front pallet to the pick face

Only the front pallet is accessible at any time, making the system suitable for LIFO inventory flows.

| Parameter | Typical Range |

|---|---|

| Pallet depth | 2–6 pallets |

| Maximum pallet weight | Up to XXXX kg (customizable) |

| Pallet size compatibility | Standard & non-standard pallets |

| Rail inclination | Engineered for controlled pallet flow |

| Cart construction | Heavy-duty steel frame |

| Wheel type | Polymer or steel wheels |

| Finish | Powder-coated or galvanized |

| Compliance | FEM / RMI / local standards |

Exact specifications depend on pallet weight, depth, and project requirements.

Push back racking systems can be customized to suit specific operational needs:

Pallet dimensions and weight capacity

Lane depth and bay configuration

Cart wheel material (noise, durability, temperature resistance)

Structural steel grade and corrosion protection

Seismic and safety accessories

Speed controllers to regulate pallet return velocity

Front pallet stops and backstops for load control

Structural design based on pallet load and seismic requirements

Designed to minimize forklift entry into rack structure

Push back racking systems are commonly used in:

Food & beverage distribution centers

Cold storage and freezer warehouses

Manufacturing buffer storage

FMCG and retail distribution

High-throughput pallet storage areas

Multiple pallets per SKU

High storage density requirements

Fast loading and unloading operations

Limited warehouse floor space

Operations requiring FIFO inventory rotation

High SKU variety with low pallet quantity

Inconsistent or damaged pallet quality

Extremely high seismic zones without specialized design

Each push back racking system is engineered based on project-specific parameters, including pallet load, warehouse layout, and safety requirements.

👉 Contact our engineering team to receive:

Layout proposals

Load calculations

System specifications

Project-based quotation

Heavy-duty racking, engineered for high load.

Custom design to fit your warehouse.

High-strength steel, built to last.

From design to installation, one-stop solution.

Request a quick quote for racking solutions.

We reply within 24 hours.

Fast quote for pallet, shuttle, AS/RS & customized racks.