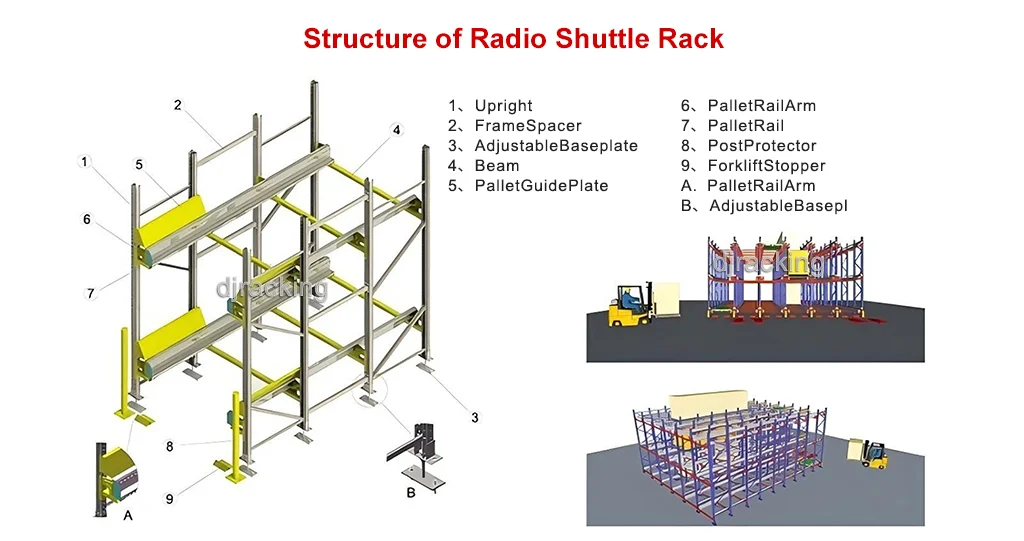

The Radio Shuttle Racking System is a high-density pallet storage solution designed to maximize warehouse space utilization and improve operational efficiency.

It combines robust racking structures with an intelligent radio shuttle that automatically moves pallets inside storage lanes, while forklifts operate only at the aisle entrance.

This system is ideal for warehouses requiring high throughput, reduced labor costs, and optimized storage density, especially in cold storage, food & beverage, manufacturing, and logistics centers.

By eliminating traditional forklift aisles, the radio shuttle racking system significantly increases pallet storage capacity, making full use of available warehouse space.

The radio shuttle automatically transports pallets along rails inside the racking lanes, reducing forklift travel distance and minimizing the risk of rack damage and accidents.

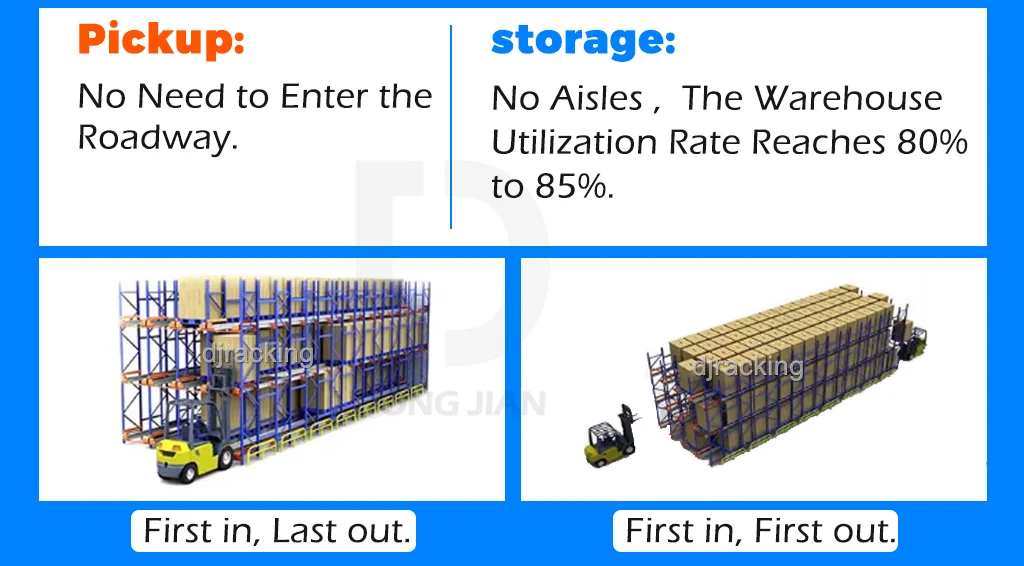

The system can be configured for FIFO (First-In-First-Out) or FILO (First-In-Last-Out) operation, depending on inventory management requirements.

Forklifts no longer need to enter deep lanes, resulting in faster loading/unloading cycles, lower labor intensity, and reduced equipment wear.

Suitable for standard, cold, or frozen warehouses, and compatible with various pallet sizes and load capacities.

The forklift places the pallet at the front of the racking lane.

The radio shuttle moves the pallet automatically to the designated storage position.

During retrieval, the shuttle carries the pallet back to the aisle for forklift pickup.

This intelligent cooperation between forklift and shuttle ensures high efficiency, accuracy, and safety.

| Item | Description |

|---|---|

| Material | High-strength structural steel |

| Load Capacity | 500 – 5000 kg per pallet (customizable) |

| Pallet Type | Euro pallet / US pallet / customized |

| Operation Mode | FIFO or FILO |

| Control System | Wireless remote control |

| Power Supply | Rechargeable battery |

| Surface Treatment | Powder coating / Galvanized |

| Color | Custom RAL colors available |

Cold storage & frozen warehouses

Food & beverage logistics

Manufacturing and industrial storage

High-volume distribution centers

Seasonal or bulk inventory storage

Customized Design – Tailored solutions based on warehouse layout and operational needs

Reliable Quality – Strict quality control for racking and shuttle components

Professional Engineering Support – Layout design, installation guidance, and after-sales service

Cost-Effective Solution – Long-term savings through efficiency and space optimization

A logistics warehouse with limited floor space increased its pallet capacity by over 60% after installing our radio shuttle racking system, while reducing forklift operation time by 30%.

Q: What is the difference between Radio Shuttle Racking and Drive-In Racking?

A: Radio shuttle racking uses an automated shuttle to move pallets, eliminating the need for forklifts to enter lanes, which improves safety, efficiency, and rack lifespan.

Q: Can the system be used in cold storage?

A: Yes. The radio shuttle racking system can be designed for low-temperature environments, including freezer warehouses.

Q: Is the system suitable for different pallet sizes?

A: Yes. The racking and shuttle can be customized to accommodate various pallet dimensions and load requirements.

Looking for a high-density, automated pallet storage system?

📩 Contact us now for a professional design proposal and competitive quotation.

Heavy-duty racking, engineered for high load.

Custom design to fit your warehouse.

High-strength steel, built to last.

From design to installation, one-stop solution.

Request a quick quote for racking solutions.

We reply within 24 hours.

Fast quote for pallet, shuttle, AS/RS & customized racks.