Cantilever racking is a specialized warehouse storage system designed for long, bulky, or irregularly shaped items that cannot be efficiently stored on conventional pallet racking. Commonly used in industrial and manufacturing environments, cantilever racking provides open-front access and flexible configuration options for storing materials of varying lengths and weights.

This guide explains what cantilever racking is, how it works, its main components, types, advantages, disadvantages, and typical applications.

What Is Cantilever Racking?

Cantilever racking is a storage system made up of vertical uprights with horizontal arms that extend outward to support loads. Unlike traditional racking systems, cantilever racking has no front columns, allowing unrestricted access to stored materials.

This design makes it particularly suitable for storing long products such as timber, steel sections, pipes, tubes, panels, and other oversized items.

How Does Cantilever Racking Work?

Loads are placed directly onto the horizontal arms, either manually or using handling equipment such as forklifts or cranes. The weight of the load is transferred through the arms to the uprights and base, ensuring stability and structural integrity.

The open design allows materials to be stored at varying heights and makes it easy to adjust arm positions as storage requirements change.

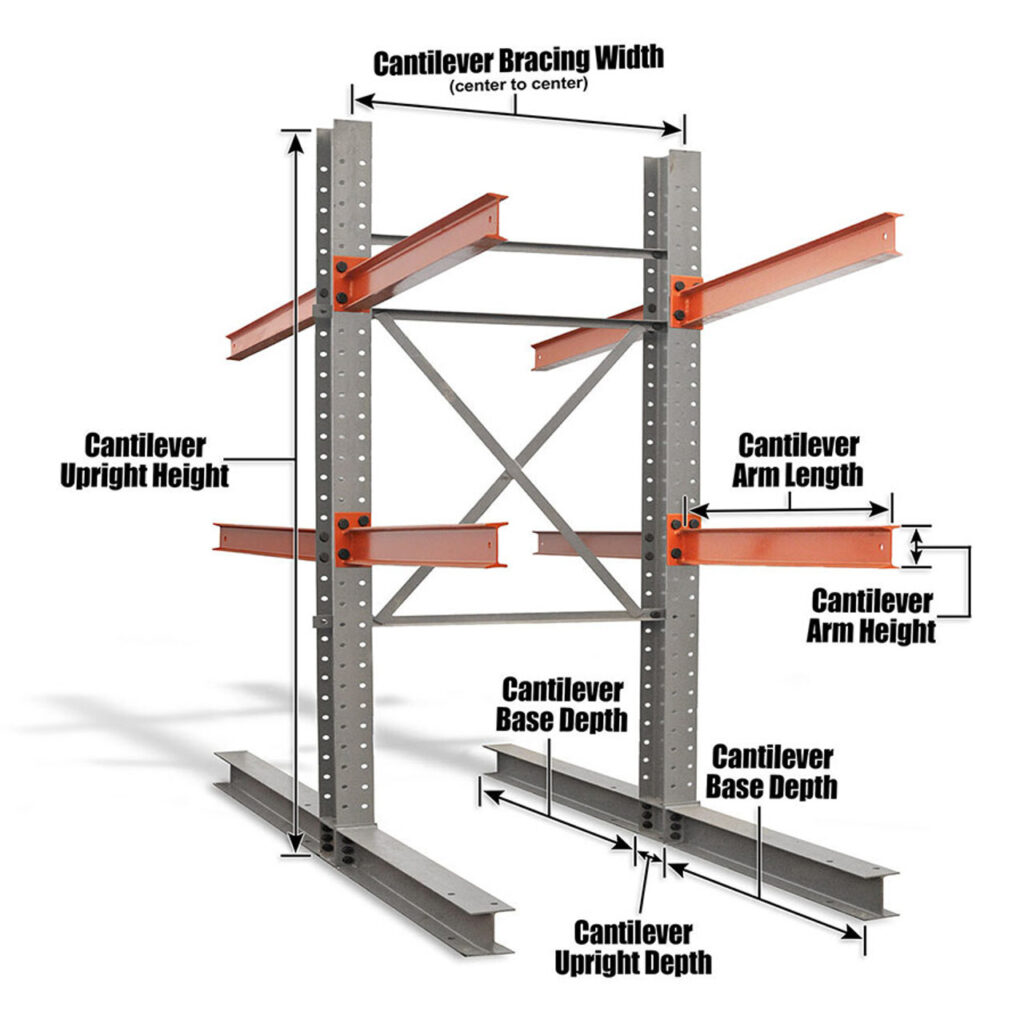

Main Components of a Cantilever Racking System

A standard cantilever racking system consists of several key components:

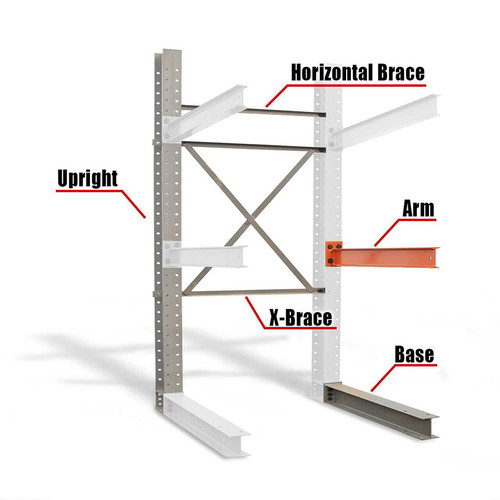

Uprights

Vertical columns that form the main structural support of the system. Uprights are anchored to the floor and designed to withstand bending and vertical loads.

Arms

Horizontal load-bearing elements that extend from the uprights. Arms can be adjusted vertically to accommodate different load sizes and are available in various lengths and load ratings.

Base

The base connects the upright to the floor and provides stability. It plays a critical role in distributing load forces.

Bracing

Horizontal and diagonal bracing elements connect uprights and provide lateral stability to the system.

Accessories

Optional accessories may include arm end stops, safety pins, load retainers, and protective coatings for outdoor use.

Types of Cantilever Racking

Cantilever racking systems are available in several configurations to suit different storage requirements:

Light-Duty Cantilever Racking

Designed for lighter loads and smaller materials, often used in workshops or light industrial environments.

Medium-Duty Cantilever Racking

Suitable for general industrial applications, offering a balance between load capacity and flexibility.

Heavy-Duty Cantilever Racking

Engineered for high-load applications such as steel beams, structural sections, and large timber products.

Single-Sided Cantilever Racking

Installed against walls or along warehouse aisles, providing storage on one side only.

Double-Sided Cantilever Racking

Allows storage on both sides of the upright, maximizing storage density in open areas.

Common Applications of Cantilever Racking

Cantilever racking is widely used across many industries, including:

- Timber and lumber storage

- Steel bars, beams, and metal profiles

- Pipes and tubes

- Construction materials

- Manufacturing and distribution centers

Its versatility makes it suitable for both indoor and outdoor storage environments.

Advantages of Cantilever Racking

Cantilever racking offers several operational advantages:

- Open-front access for easy loading and unloading

- Flexible arm positioning for different load sizes

- Efficient storage of long and bulky items

- Scalable design for future expansion

- Suitable for indoor and outdoor use

These features help improve warehouse efficiency and material handling safety.

Disadvantages of Cantilever Racking

While highly effective, cantilever racking also has some considerations:

- Higher initial investment compared to basic shelving

- Requires proper design to ensure load safety

- Not ideal for small, palletized goods

Careful planning and professional system design can help mitigate these factors.

How to Choose the Right Cantilever Racking System

When selecting a cantilever racking system, consider the following factors:

- Length, weight, and type of stored materials

- Required load capacity per arm and per bay

- Available warehouse space and ceiling height

- Indoor or outdoor installation requirements

- Handling equipment used

A well-designed system ensures long-term safety, efficiency, and adaptability.

Conclusion

Cantilever racking is an efficient and versatile storage solution for long and oversized materials. Its open design, adjustable configuration, and high load capacity make it a preferred choice in many industrial and warehouse environments.

For businesses requiring a tailored storage solution, professional system design and engineering support are essential to achieve optimal performance and safety.